- How to order

- FAQ

- Shipping

- Privacy Policy

- Returns and Refund Policy

- Terms and conditions

- Payment

- Become a Partner

Address

245 N Highland Ave STE 230 #96 Atlanta, GA 30307

Contacts

Phone:

(+1) 678 7015 978

info@saintdiamonds.com

Diamonds grow in extreme high-pressure and high-temperature (HPHT) environments in the Earth’s mantle, 95–155 miles (150–250 kilometers) below the Earth’s surface.

SAINT DIAMONDS laboratory recreates this natural process of HPHT (3,000ºK, 60,000 Bar) and transforms the carbon from your loved one’s remains into real diamonds.

Turning ashes or hair into diamonds is possible because carbon comprises about 19% of the human body, and diamonds are carbon in a crystal form. Cremation diamonds are real diamonds that are grown thanks to the carbon present in human remains (hair and cremation ashes).

Nitrogen is also present in the human body, but it makes up only about 3% of the body. This element gives the memorial diamond a yellow color, which varies from a light yellowish tone to a dark orange.

We also produce colorless cremation diamonds by removing the nitrogen from the carbon before the crystallization process begins.

The first stage is to analyze your loved ones’ remains to determine if they contain the right amount of carbon to create a diamond. The amount of carbon present in the remains differs, and there may be a slight chance that there is not enough carbon for our company’s creation procedure.

We usually suggest our customers provide extra hair samples to keep them as a backup plan.In this stage, we work with an element analyzer to determine the amount of carbon present in the remains.

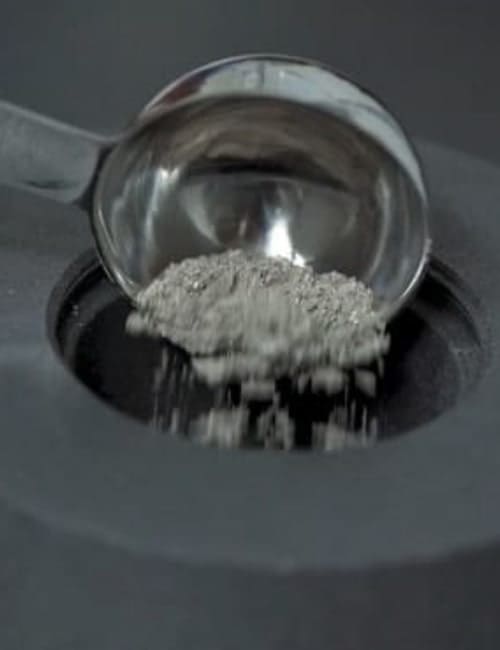

We mix an impurity remover with a particular solvent to extract unstable chemical particles. The remains (hair and ashes) are ground and then stirred into a micro powder while in a chemical gas atmosphere.

Our impurity remover will attach itself to any impurity it finds, which will then be isolated during the centrifuge process.

We also apply a few technicalities to keep the carbon rightfully stored, with any other elements being diminished to the minimum.

The grinding process can be compared to the Earth’s motions: rotation and revolution.

Purification at Extreme Temperatures

In this stage, the now-purified material gets heated to high temperatures so that any extra impurities can be eliminated. In this process, oxygen is expunged, and other protective gasses are introduced to keep the remains from oxidizing.

Then, we apply double handling for the chemical extraction. Sometimes, we need to apply a high voltage in an airtight

canister to purify the carbon even more.

We usually use a gas mix to preserve the remains from oxidizing.

Soaked-chemical Carbon Purifying Process

The extracted carbon is taken into a resistant case in a wet, chemical atmosphere to boost the levels of purity. The software-controlled process controls the temperature, stirring speed, and extra chemical agents to ensure the quality of the carbon. In this final purification stage, the purity will reach a 99.99% level. In the case that the purification doesn’t reach this milestone, we can add extra purification processes to get rid of any remaining impurities.

A chemical specialist is in charge of enhancing the purity during this stage

The HPHT crystallization process transforms the purified carbon atoms into a genuine diamond.

In this stage, the purified carbon we got from the remains is turned into flake graphite in the shape of a cylinder. This cylinder is encased in protective elements, preparing the carbon for the final stages where pressure, insulation, temperature control, and protection will be required.

The crystallization process can take a modest number of days or sometimes months to complete; it all depends on the size and color of the cremation diamond.

Our rough cremation diamonds get mixed using graphite, especially on their outer surfaces. These diamonds then get polished by experts who only work with our created diamonds.

If you need, you can request a rough uncut diamond as long as you don’t have cut it elsewhere afterward; the vast amount of diamond cutters lack the experience cutting cremation diamonds and end up breaking the diamonds.

If you want us to re-polish your diamonds or set them into your cremation jewelry pieces, contact us here.

Every SAINT DIAMONDS cremation diamond is delivered with a Certificate of Origin, along with a processing analysis report in which we document and scientifically prove that your memorial diamond was, indeed, created from the remains (ashes or hair) of your loved one.

Every production record, piece of lab data, and chemical and physical analysis from our company can be re-validated by the independent certification institute of your choosing.

The use of fluorescence and luminescence tracing, such as shortwave ultraviolet light is very popular in diamonds analysis. Our lab works with even better and highly-technical examination instruments. Cremation diamonds look the same both chemically and visually as a mined natural diamond. Nevertheless, our experts can scientifically confirm the differences between a memorial diamond and its natural counterpart due to minor details in the atomic structure, as well as the chemical density.

The remains go through a purification process to achieve a 99.99% purity level. This process is done for every cremation diamond ordered. All the impurities are isolated and reduced to 1/500 of their original level, thus giving us a 99.99% purity level.

We care for each detail when it comes to turning ashes or hair into diamonds. We work with the most advanced equipment, which allows us to deliver real works of art. The instruments we use are medical-grade and provide extremely high accuracy.

The water is purified with an ultrapure system down to 18 MΩ.cm (1.3 times purer than normal drinking water). Every chemical container we use is cleaned with this ultrapure system to avoid any external impurities from entering the process.

As you may know, the purified carbon is the essence of the whole crystallization process. During this stage, oxygen and water are removed to make sure the carbon gets purified to its maximum level.

The colorless diamond grows slowly but steadily at about 0.5–1 mg per hour. This rate means that a one-carat diamond usually takes about one month to grow to its usual size. However, because the growth is very slow, the diamond tends to show little to no flaws plus a great structure.